Manufacturing facility in Dübendorf. At our workshop in our factory building in Dübendorf, historical and modern machines meet perfect craftsmanship and production expertise. A large part of Lehni's manufacturing takes place here. Many crucial steps of the process are carried out by hand.

Swiss Made

Truly Swiss made. At Lehni, “Swiss made" actually means made in Switzerland and involves everything from design to manufacturing and administration. Roughly 80% of our manufacturing takes place in the workshop in Dübendorf, and the remaining 20% are largely produced in the surrounding area.

Guaranteed quality

Lehni represents perfection down to the last detail. By manufacturing locally, Lehni is in control of the entire manufacturing process and can ensure compliance with high quality standards.

Highest precision

Perfect mechanisms, seamless surfaces, exact assemblies: absolute precision is a must for Lehni. This requires the exceptional skills of specialist craftsmen who are hard to come by outside of Switzerland.

Fewer emissions

At Lehni, Swiss made also translates to short distances. Since our components do not have to be transported around the world, unnecessary emissions can be avoided – to the benefit of our environment.

Reliable production & delivery

Due to local production, our delivery dates are hardly affected by global issues with respect to logistics and bottlenecks.

Metal expertise

Perfection in reduction. Making Lehni furniture means transforming minimalist designs into light, innovative constructions with hardly any visible traces of processing.

For over 100 years, the name Lehni has been synonymous with high-quality metalwork. Exceptional skills are required for the manufacturing of the furniture collection. Over the years, we have perfected our expertise regarding the intelligent execution of form and function.

Aluminium sheets processed by bending and stamping are turned into stable elements that form an object when joined together. The Side Table is an example of this Lehni design principle.

Lehni manages to omit more than seems feasible. The shelf, for example, is radically reduced in form and cleverly designed and produced, making it economical in its use of materials.

Bending and stamping

During processing, Lehni uses the particular properties of aluminium and a specially developed bending technique. The shelf, for example, is made of a light, thin aluminium sheet that only achieves the necessary load-bearing capacity thanks to a fold along the longitudinal edges. This form of processing, which Rudolf Lehni junior had already developed and patented when he was a tinsmith, became a central manufacturing feature of Lehni.

Lehni uses various mechanical techniques to process over 20 tonnes of aluminium, sheet steel, and other metals per year. By combining different processing techniques such as stamping, laser-cutting and bending, we give the sheets the shape and stability required for the respective application.

Sustainability

Circular principle. The idea of a circular economy is in Lehni's DNA – beginning with a smart design and extending to a piece’s recyclability at the end of its life cycle.

Sustainability at Lehni

Sophisticated construction

All Lehni furniture focuses on the essentials. The pieces are cleverly designed and radically reduced in form. Accordingly, they are also economical in terms of the materials used – both for the piece of furniture itself, but also for its packaging.

Timeless design

With its simple elegance and clear, timeless design, Lehni furniture outlasts fashions and trends. Lehni pieces never have to be replaced because they stand the test of time.

Longevity

Lehni furniture is manufactured with the utmost care and precision from high-quality, durable materials. As a result, the furniture has an above-average lifespan.

Local production

All components for Lehni furniture are manufactured in Dübendorf and its surrounding area, thus avoiding unnecessary emissions caused by transport.

Second Life

Lehni furniture is in high demand on the second-hand market. If you would like to sell your Lehni piece, you will quickly find someone interested in giving it a second life – and will probably sell for a good price

Completely recyclable

Lehni takes back all its furniture in order to recycle it professionally. Aluminium, in particular, is almost completely recyclable and thus reusable.

Repair

In general, Lehni furniture is very durable. However, we can also repair and refurbish it professionally if necessary. For a longer life, even across generations.

Materialisation

Lehni is mindful when it comes to using sensible materials – by utilising aluminium consisting of 40% recycled material, for example, and by optimizing the cutting of sheet formats to avoid material use and waste.

The circular lounge chair

The Ensō Lounge Chair is a collaboration between Lehni and Qwstion and is fully committed to the circular economy concept. Go to product

Materials

Durable and well-conceived. Lehni carefully selects materials in accordance with the requirements for sustainability, aesthetics, and processing options.

Aluminium

The use of aluminium is characteristic of Lehni furniture. Aluminium is durable and can be fully recycled. The recycling process saves up to 95% of energy in comparison to primary production. Lehni largely uses aluminium consisting of 40% recycled materials in the manufacturing process.

Metall

Lehni mostly uses the metal aluminium, which can be fully recycled. However, parts made of steel can also be melted down and fully recycled at the end of their life cycle. Copper and brass are also used for customised products.

Linoleum

Linoleum consists of 100% organic and mineral raw materials, over 80% of which are renewable – such as flaxseed oil. Linoleum is characterised by its unmistakable feel and its silky matte, pleasantly warm and elastic surface.

Fabric

Lehni mainly uses fabrics by Kvadrat and the textile fabric Bananatex®. Kvadrat was founded in Denmark in 1968 and manufactures high-quality modern textiles and textile-related products.

Bananatex® is made from naturally grown Abacá banana plants. It’s largely manufactured in Switzerland and is biodegradable. Bananatex® has been awarded the Cradle to Cradle Certified® Gold certificate, the world's most advanced standard for products that are manufactured in a circular and responsible way.

Wood

As a natural material, wood has individual structures and colours that make each piece of wooden furniture unique and change colour over time. Lehni uses wood in a variety of ways, e.g. as veneer, plywood, chipboard, paper, cardboard, or solid wood. We purchase wood and wood-based materials in Switzerland. This enables us to ensure that the Swiss Timber Trade Regulation and the requirements of the European Timber Regulation (EUTR) are met and that only FSC or PEFC certified wood is used.

Plastic

Plastic is one of the most innovative materials of the last century. It can be moulded into any shape, enables the implementation of new concepts, and is often durable and weatherproof. As a manufacturer, Lehni is aware of its responsibility in dealing with plastics and uses them sensibly to limit the impact on the environment.

Finishing

Surface treatments. Many of our pieces of furniture are available in different finishes. Depending on the material and the desired effect, we use different techniques for surface treatments.

Anodising

Anodised surfaces are durable, render unrivalled colour, and have a warm and soft feel. Anodising is an electrolytic process used to create a hard oxide layer on an aluminium surface that is resistant to abrasion and scratches, making aluminium more durable and long-lasting. The process can be used to produce different colours, including the typical Lehni "colour" clear anodised aluminium.

Powder coating

Powder coating is a type of coating applied to metal. It lends the surface a high technical and mechanical resilience and protects it from scratches and corrosion. The process allows a very wide range of colours to be used (according to the RAL or NCS colour chart for Lehni products) and is also environmentally friendly (no solvents are used).

Bare aluminium

Bare aluminium is largely untreated. It’s characterised by a silver-grey, slightly shiny surface. Bare aluminium profiles already are corrosion-resistant and do not oxidise. Lehni uses bare aluminium for the Aluminium Shelf and the Bookshelf.

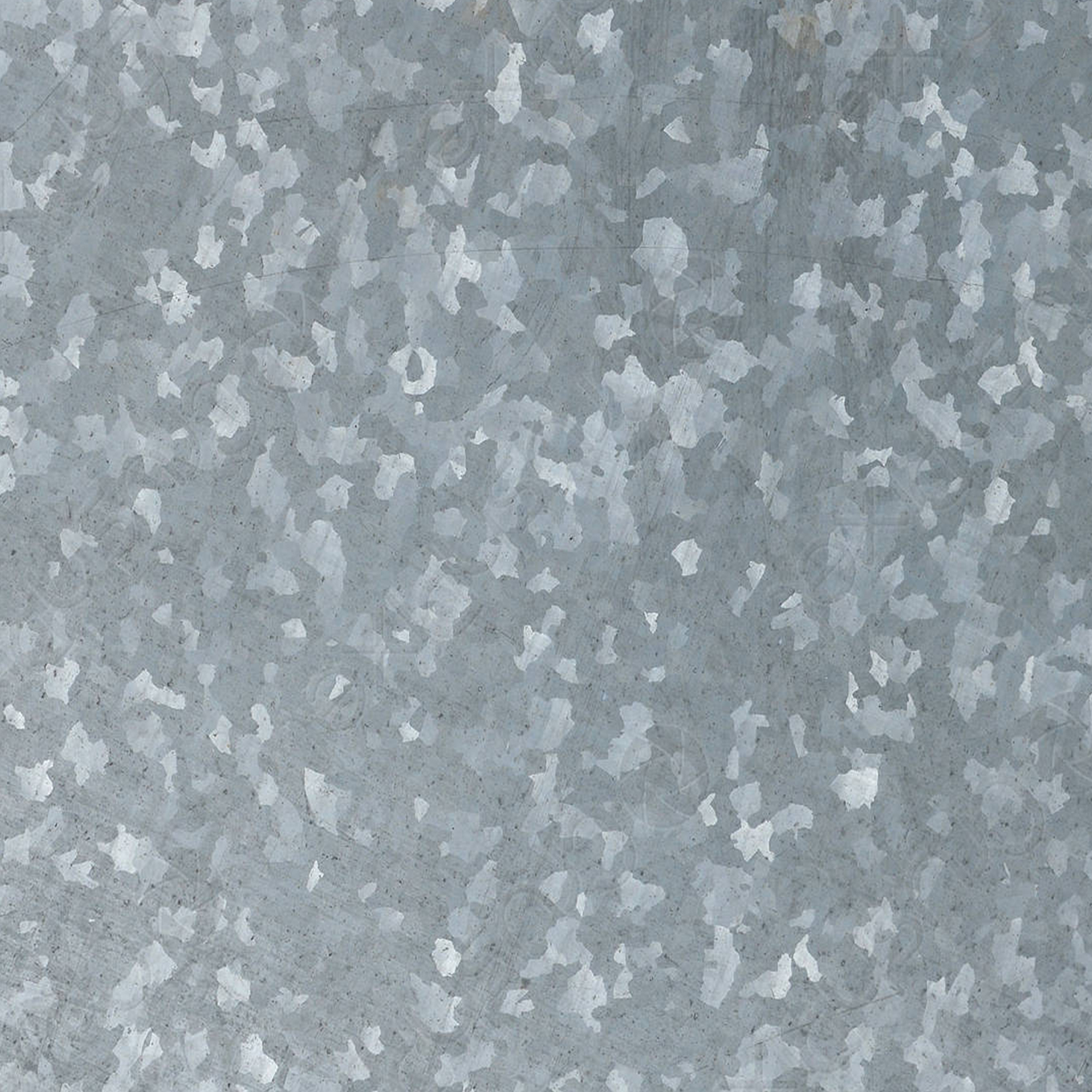

Hot-dip galvanising

Hot-dip galvanising is a process used to protect steel from corrosion. A metallic zinc coating is applied to iron or steel, which results in an extremely durable corrosion resistance and a shiny metallic surface. Lehni uses the process for the Shoe Storage and certain table legs.